Rotary Systems Partners With Automation Company To Streamline Grocery Packing Process

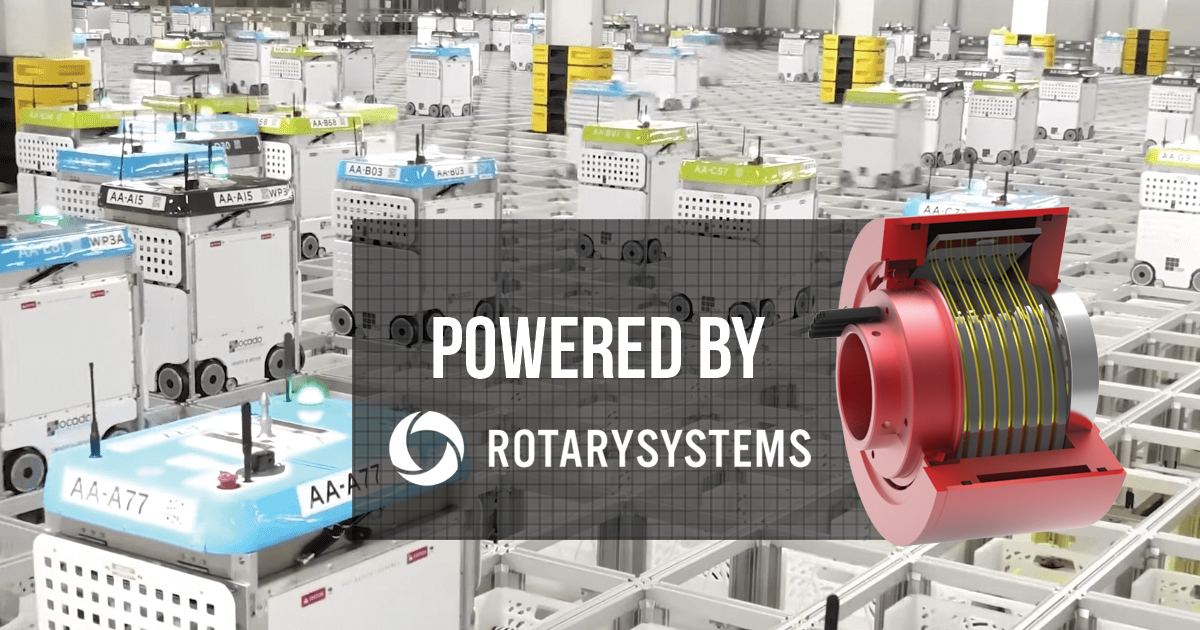

Ramsey, Minnesota—Rotary Systems is proud to partner with an automation company in the United Kingdom who manufactures robots for a technology business that is revolutionizing online shopping.

On average, retail inventory is only 63% accurate. Implementing automation throughout the warehouse would increase productivity by at least 30%.

Our customer is currently using our slip ring to create grocery packing robots for their client. We made them a custom electrical slip ring specifically for this purpose. Over the last three years, we’ve built thousands of custom slip rings for their robots.

Disrupting The Market

The slip ring is an important component in a ground breaking technology solution which is disrupting markets globally.

Their client is now looking for additional warehouses to use for their operations—growth has been exponential!

Securing the Future of Warehouse Workers

In 2016, there were 5 workplace injuries for every 100 full-time workers in the warehouse/storage industry.1 By repositioning physical warehouse workers into more appropriate pick-and-place positions and incorporating more grocery packing robots, they can avoid these types of injuries in the future.

Now that these packing robots have streamlined the grocery packing process, consumers can buy their groceries online with increased confidence. The robots can even check inventory against expiration dates to decrease waste across the entire supply chain.

By focusing on the consumer experience, our customer’s client is taking grocery shopping to the next level and bringing making the future a present reality.

Rotary Systems, Inc., located in Ramsey, Minnesota, is a leading design and manufacturer of custom and standard rotary unions and electrical slip rings components that are used in various industries around the world. Founded as a privately held company in 1992, the organization has grown into one of Minnesota’s leading technology companies and has enjoyed over 20 straight years of business growth and profitability with more than 1,000 customers located in over 25 countries. Rotary System’s vision is to be the premier global leader in the design, development and manufacture of both rotary unions and electrical slip ring products for industries in all markets around the world.