When you’re thinking about how to choose a suitable slip ring, picking the right model requires being thorough and specific. As with most crucial mechanical components in larger systems, not choosing the right slip ring could lead to serious issues. Considering that, how do you make your choice? In this article, we’ll go over the most important considerations in this regard.

Picking A Proper Slip Ring

These days, having a data connection that’s fast enough is incredibly important — particularly when we take the automation industry into account. In this sector, manufacturing slip rings capable of enhancing power transmission is paramount. In 2020, high-level automation reached a tipping point and now large bandwidth data transmissions are a requirement. That’s where slip rings come in. Electrical slip rings are excellent at enabling quick data protocols without technical issues like power interruption.

There are plenty of applications of slip rings for both domestic purposes and in industrial complexes. Companies move slip rings and transport machinery anywhere in the country because the demand for them is rising.

With that in mind, taking the right factors into consideration while striving to choose a suitable slip ring for your specific purposes is important. The first thing you need to think about here is what are you using the device for? And will a slip ring enhance the way you use it?

In a big way, the slip ring you choose will correlate to the output that you expect from your device. But before we tackle all the details — we need to go over what slip rings are actually used for.

Electrical Slip Ring 101

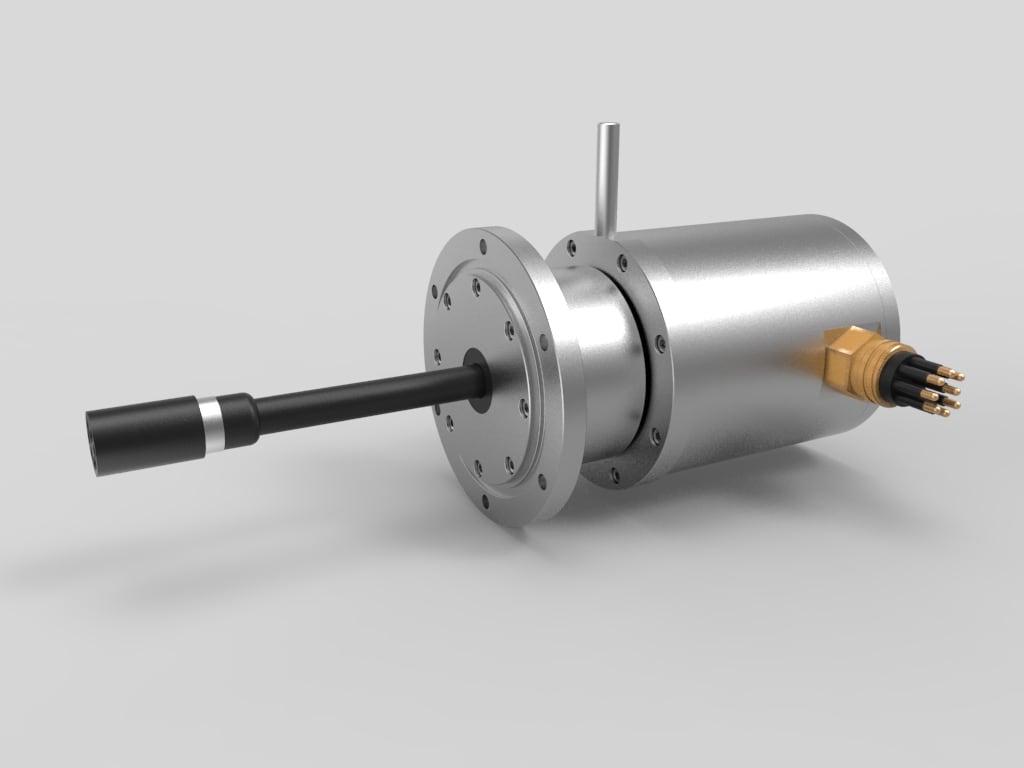

These are devices designed to enable an electrical connection that’s stable enough for a continuous flow of power — and in practice, data — or a signal emitted to rotating equipment from a stationary position. These rings allow for a strong electrical signal and thus a stable transfer of data. And when you’re looking for the perfect one for your project, there are a couple of things you need to keep in mind:

- Conducting ring specs

- Stationary brush types

- Power requirements

Conducting Ring

If there is one aspect of a slip ring that’s important for its long-term durability, it’s how big or small the conducting ring is. Remember, this conducting ring constantly comes into contact with the slip ring’s stationary brush. This means that it’s exposed to constant friction, gradually scrubbing off the contact surface.

The bigger your conducting ring is, the bigger the chances are of wear and tear — because the surface area that’s sliding against the stationary brush is bigger as well. Because of this, smaller conducting rings increase the lifespan of your slip ring.

On the other hand, there are reasons for using bigger conducting rings as well — larger ones allow for additional use of the through bore, such as fluid transmission.

Stationary Brush

Your choice of a stationary or sliding brush depends on a couple of different parameters. Usually, we have to consider the power and signal requirements such as:

- Impedance

- Speed of rotation

- Voltage

- Bandwidth

- Operating temperature

- Resistance temperature

There are three varying kinds of stationary brushes:

- Mono-filament

- Composite graphite

- Poly-filament

Composite brushes are manufactured from a material called carbon graphite — after being mixed with metals with high conductive properties, it increases current density. This type of brush is used in systems that have incredibly high motor speed and power requirements.

Mono-filament brushes are produced using precious metals — often enough it’s gold. This kind of brush is used with lower speeds and power levels. They’re also great in situations where signal strength is important.

Poly-filament materials are used for the production of slip rings with different requirements — usually, with low contact resistance and minuscule brush noise. If you want to choose a suitable slip ring in accordance with your stationary brush, the factors you need to consider are the application of the slip ring, data rates, your targets, etc.

Power Requirements

In the process of choosing a suitable slip ring, one of the major deciding factors is the power level needed for the optimal functioning of your system. Also, you should pay less attention to power at the electrical load than to the ring’s current flow and voltage drop.

The reason for this is the fact that the voltage drop affects how power gets dissipated within your system. Having a subpar voltage drop will result in the dissipated power becoming heat — thus raising the device’s operating temperature.

Conclusion

So, considering all of this, what are the questions you need to pose before settling on a specific slip ring? If your goal is to achieve the largest amount of value and effectiveness, it doesn’t matter whether you’ll be using it for industrial or commercial applications — the factors remain the same.

You still need to think about the kind of application in which you’ll be implementing the slip ring. The purpose of the slip ring and your selection will also depend on the application’s signal requirements, bandwidth, etc. Many of them are specifically designed for lower power resistance and clearer signals, while others function at higher speeds; naturally, this depends on some components such as the slip ring’s brush.

As always, if you need help finding the perfect slip ring for your unique application, we’re all ears. Contact us, today, and we’ll get started on your project immediately.

Rotary Systems, Inc., located in Ramsey, Minnesota, is a leading design and manufacturer of custom and standard rotary unions and electrical slip rings components that are used in various industries around the world. Founded as a privately held company in 1992, the organization has grown into one of Minnesota’s leading technology companies and has enjoyed over 20 straight years of business growth and profitability with more than 1,000 customers located in over 25 countries. Rotary System’s vision is to be the premier global leader in the design, development and manufacture of both rotary unions and electrical slip ring products for industries in all markets around the world.