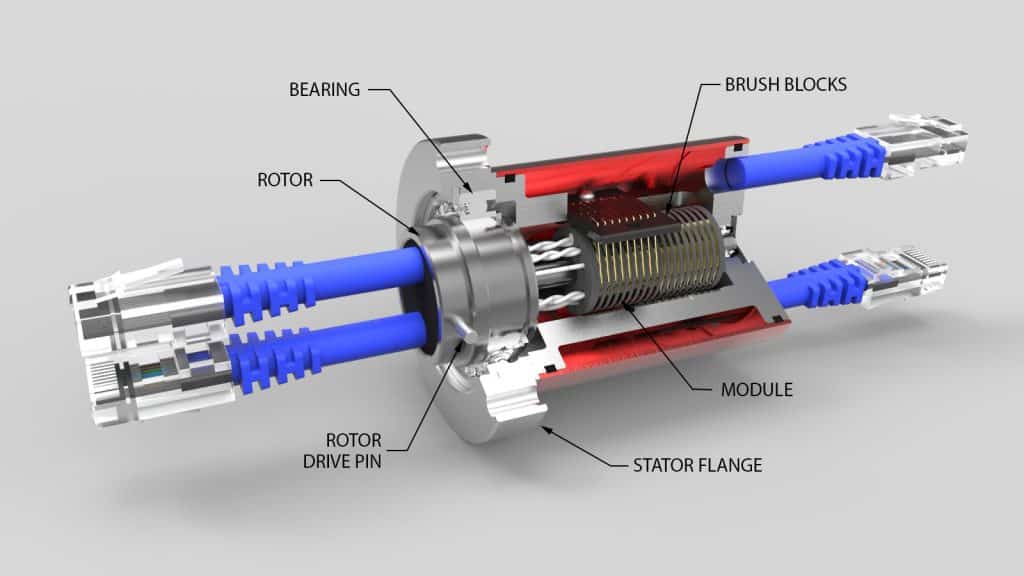

Here is an example of what it looks like on the inside of a slip ring.

A slip ring is an electrical collector that carries a current from a stationary wire into a rotating device. Slip rings consist of a stationary graphite or metal contact brush which rubs on the outside diameter of a rotating metal ring. As the metal ring turns, the electrical current is runs through the stationary brush to the metal ring making the connection. Slip rings usually operate with multiple rings, providing an even flow of current to multiple portions of a device. Read our entire slip ring definition to learn more.

The wires from the stationary structure loop around the module which houses the electricity conducting rings. The slip ring receives power when the wire of the brush block comes in contact with the connecting wires in the slip ring. This electricity transfers from the brush wires to the metal rings, and from there transfers the electricity outside the slip ring to the device.

Common uses for slip rings are for power, proximity switches, strain gauges, video, and Ethernet signal transmission. By and large, they are available in a wide variety of configurations, termination types, and materials to fit most applications. For the most part, rings usually operate with gold-on-gold systems for low current signal circuits or silver-to-silver systems for higher current power circuits. You can find them in electrical generators, alternators, in packaging machinery, cable reels, and wind turbines. Overall, slip ring technology is extremely diverse and has applications in just about any industry.

Slip rings for automation

Alternate names can include rotary electrical interfaces, rotating electrical connectors, and electrical collectors.

Slip rings do the same for electrical power and signal that rotary unions do for fluid media. They often integrate into rotary unions to send power and data to and from rotating machinery within a single device.

To begin, some basics to think about when selecting the right slip ring for an application are the physical dimensions in which the device will be operating. Also, circuits required with maximum current and voltage, and operating environment specifics should be taken into consideration. Meanwhile, please refer to the part by part breakdown below for selecting the best possible slip ring for your application.

The first thing you’ll need to define is the type of assembly required of which there are two basic types:

In addition, you should also consider the amount of available space when thinking about overall ring configuration.

The drum slip ring type is most common. We use the pancake slip ring when axial length is limited. The available space within the system will define the mechanical envelope. Consequently, by giving up the maximum space available in the system to the slip ring you will increase the chances of utilizing an existing design.

Define the electrical requirements. By specifying the current we can propose an assembly with the correct ring cross-section, brushes and termination. The voltage required will determine the spacing between adjacent rings and brushes. Therefore, you want to specify the current and voltage of each ring or group of rings individually. In summation, this enables us to provide the most economical solution within the smallest space envelope possible.

The operating speed is a critical consideration in defining the mechanical requirements. The speed, diameter and the required operating life of the application will dictate which contact materials are suitable. Will the assembly rotate at a continuous speed or will it oscillate?

Not finding a match for your application? Contact us today and speak directly with one of our skilled application engineers about your application. We can help determine the best match for your application and we can put together a custom design quote. We will design a build to fit your application perfectly.