A rotary union is a device that enables the transfer of media from a stationary source to a rotating source without cross contamination or leakage.

A rotary union allows for the movement of a fluid media (oil, coolant, water, etc) from a stationary device (a sink, an oil tank, a vat, etc) to a moving device (an engine, propeller, turbine, etc). This works when you secure the input valve to the stationary media source and attach= the rotating machine to the outlet valve. This rotates concurrently with the machine while in operation, which provides a constant fluid transfer. If operated within its appropriate use, you can see years of uninterrupted media transferring service.

A rotary union is also referred to as a rotating union, rotary joint, swivel union, or a swivel joint depending on the type of environment the device is required for. They all function the same way.

Rotary Union Definition

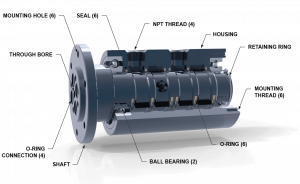

Rotary unions come in many shapes, sizes, and configurations depending on the type of use the device will experience. With these varying compositions, they all have two things in common: a shaft and a housing unit. The shaft is the component that carries the media through the rotary union to its final destination. The housing unit is the component that keeps the rotary union and the media transfer intact. Other common components include seals, bearings, retaining rings, and O rings. This depends on how complex the media and type of environment the rotary union will be used in.

Rotary unions come in many shapes, sizes, and configurations depending on the type of use the device will experience. With these varying compositions, they all have two things in common: a shaft and a housing unit. The shaft is the component that carries the media through the rotary union to its final destination. The housing unit is the component that keeps the rotary union and the media transfer intact. Other common components include seals, bearings, retaining rings, and O rings. This depends on how complex the media and type of environment the rotary union will be used in.

Rotary unions can vary in size and complexity. Because of this, they can be made with more than one passage to provide multiple types of media transfer within a single device. These types of rotary unions can handle various pressure and rotational speeds. Typically, the larger number of passages, the lower speed and pressure it can handle.

Slip rings do the same for electrical power and signal that rotary unions do for fluid media. Integrated rotary union slip ring assemblies can send power and data to and from rotating machinery within a single device. This type of all-encompassing media transfer system is becoming more common in various industries. We are the first company to offer a single source assembly for this product. Rotary Systems sets the standard for the functionality of this complex device.

What do you need to know to specify a rotary union for an application?

Here are some basics to think about:

- The physical dimensions in which the device will be operating

- The speed (RPM) the device will be rotating at

- The pressure (PSI) the media will travel through the device at.

While considering these specifics, please refer to the part by part breakdown below for selecting the best possible rotary union for your application.

Part by Part Breakdown

First, take measurement into account. What sort of restrictions, if any, are there with the design of the rotary union. These considerations also include thread type and passage size.

Material considerations can play a role in certain applications as well. We typically make our rotary unions with black carbon steel or stainless steel, but we can use most metals, as well.

You should also address the type of media, early on. Some media can play a role in limiting materials. For instance, food grade rotary unions are made with stainless steel.

Food grade rotary unions can only be made with stainless steel.

The number of passages is another consideration to think about. Our standard rotary union lines go from single passage to twelve passages, and our custom designs can go up to any number of passages needed.

Feel free to browse through our standard product lines to compare these specifics with those of your application. If our standard line of products is not a match for your application, consider browsing through our custom designs. Then, you’ll see the variations of rotary unions Rotary Systems has made for industries around the world.