Rotary Systems is the only manufacturer to offer diverse rotary union technologies such as mechanical seals, Teflon seals, hydrostatic seals and integrated electrical slip rings. We’ve never been one to turn down a challenge or fail to meet the toughest, most stringent demands and needs of our customers. This is what has made Rotary Systems the industry leader in the design and manufacture of standard and custom rotating unions.

From our skilled engineers and workers to our state-of-the-art facility to our incredible depth of knowledge, you can trust Rotary Systems to always deliver rotating unions designed and built to the highest standards possible. Yours.

For over two decades, engineers around the world have counted on our 80 years of combined engineering expertise—the most in the industry—to turn their visions into reality. Rising to the task, time and again, Rotary Systems has custom built over 700 unique rotating unions to date.

The demands and uses of rotary unions are vast. We’ve worked with engineers form a variety of industries including Automation, Defense, Offshore, Semi-Conductor, and Food and Beverage Processing. All of our standard and custom rotary unions and slip rings can be customized to your needs, including material, thread seal, passage, slip ring options.

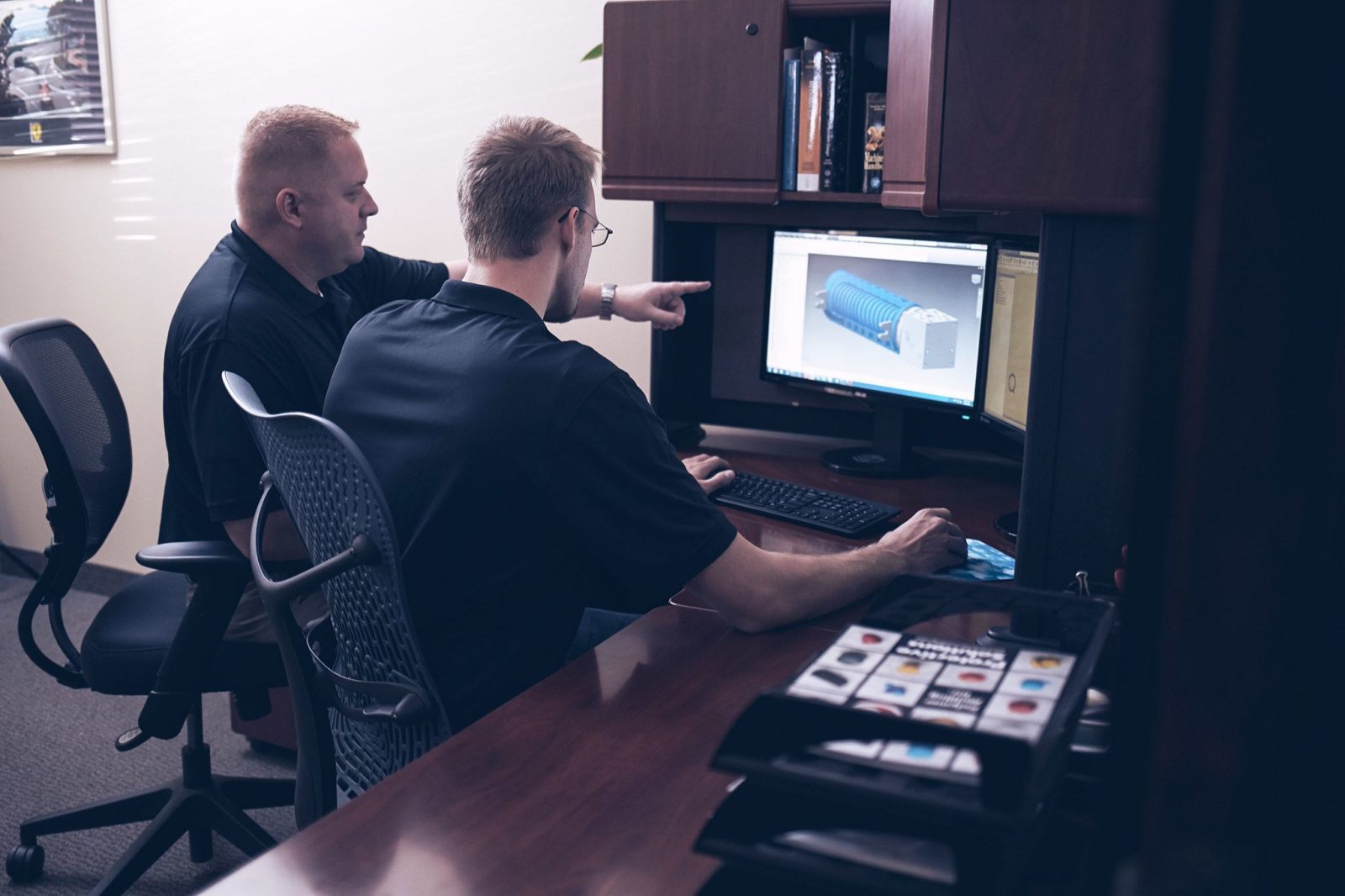

From the engineers who translate your requirements into product specs to the skilled technicians who operate our state-of-the-art manufacturing equipment to the assembly team who test each unit we make in order to ensure strict quality control. We share your passion for a successful outcome.

We have combined the finest minds in the business, the latest technology and equipment—bringing you stunning, real world solutions.

Rest assured, everyone who touches your project shares your passion for a successful outcome. From the engineers who translate your requirements into product specs to the skilled technicians who operate our state-of-the-art manufacturing equipment to the assembly team who test each unit we make in order to ensure strict quality control.

Our 30,000 sq. foot manufacturing facility where the finest rotary unions on the market are designed, manufactured, and shipped worldwide. As the leading slip ring manufacturer, we employ the latest CAD/CAM technology, high-precision lathes, and multi-function mills, and are capable of machining parts up to 60” in diameter. Our clean, brightly lit facility breaks away from manufacturing facilities of old, offering a clean and safe place to work.